Features of Vibration Stainless Steel Sheet

Our vibration stainless steel sheet combines aesthetics with durability, which is perfect for spaces that demand both style and strength.

- Aesthetic Appeal

- Scratch and Wear Resistance

- Corrosion Resistance

- Long-Lasting Durability

- Low Maintenance

Reliable Vibration Stainless Steel Sheet Supplier

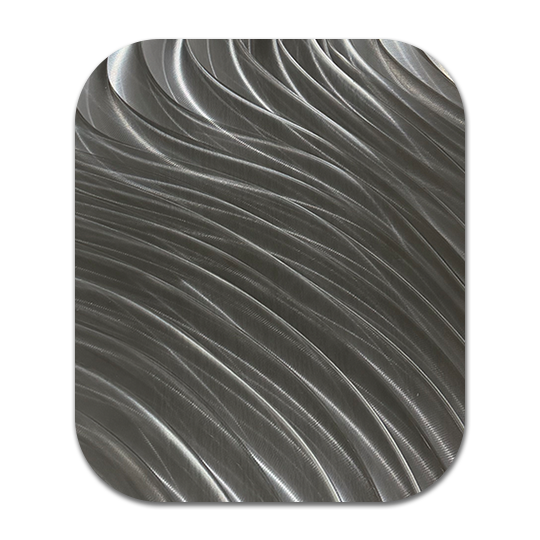

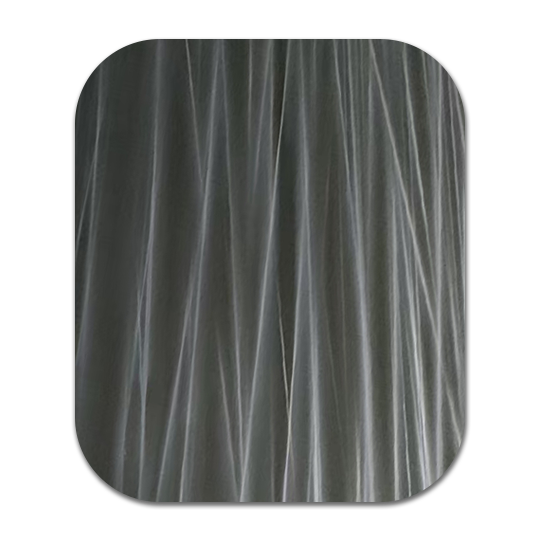

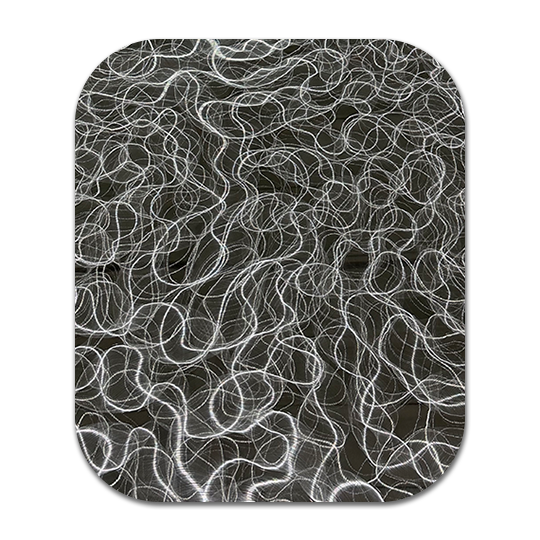

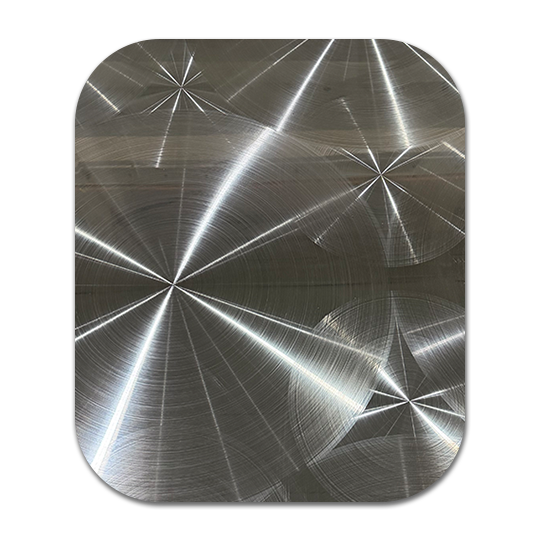

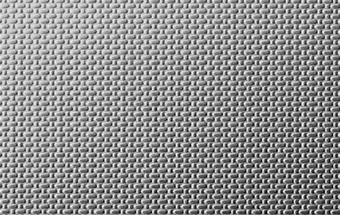

The Vibration Stainless Steel Sheet features a uniform, high-density texture formed by random, multi-directional curved lines, which is also known as non-directional Satin and Angle Hair finish. Vibration finish creates a fine surface of stainless steel sheet with soft light diffusion and a warm, elegant glow, making it ideal for designs of luxury and contemporary appeal.

BWT has contributed to providing vibration stainless steel sheets for over 10 years. With the ability to hide scratches, fingerprints, and minor imperfections, our vibration stainless steel sheets are ideal for high-traffic or high-touch environments like elevators, wall panels, kitchens, and interior surfaces.In addition to Vibration finish stainless steel, BWT can also manufacture stainless steel sheets with different patterns, such as water ripple, matte, brushed, hammered, perforated, etc., to meet the diverse needs of your projects.

We offer a range of customization options for vibration stainless steel sheets to meet your project needs. You can choose from various stainless steel grades (304, 316), thicknesses, widths, lengths, and surface colors such as Silver, Gold, Rose Gold, and Black. We also provide added surface treatments like PVD coating, etching, or anti-fingerprint coating.

Get in touch today to get vibration stainless steel sheet that matches your design vision.

What We've Made

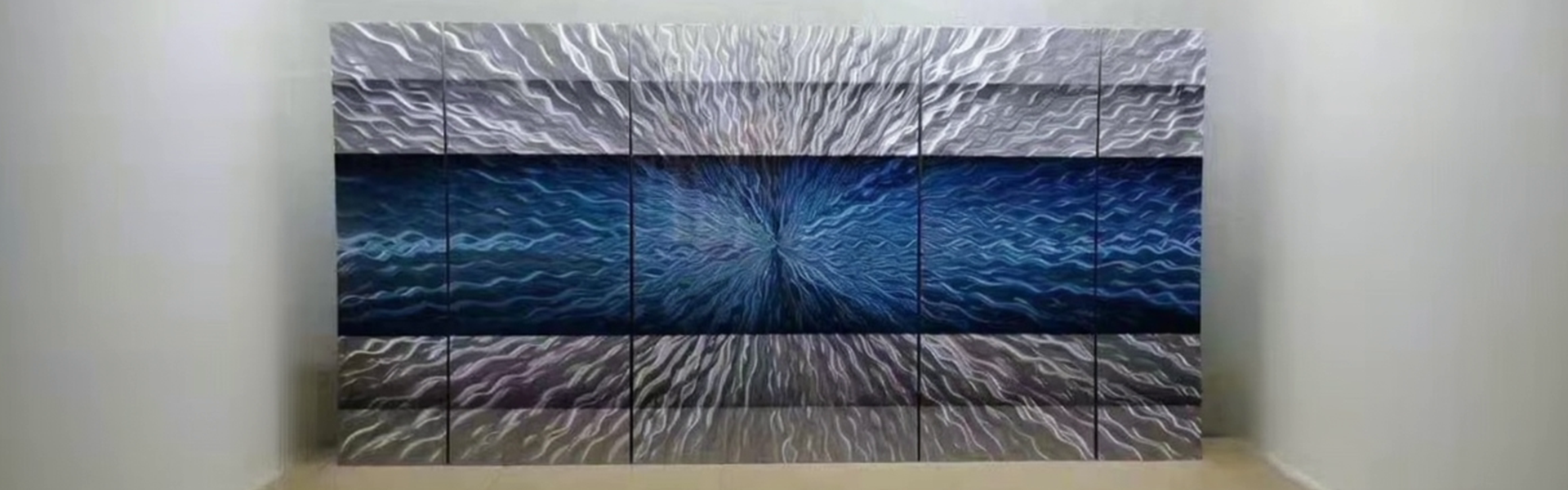

BWT’s Vibration finish stainless steel can be used on elevator panels, giving them a premium look while maintaining practicality. The fingerprint-resistant surface treatment makes daily cleaning easy and helps maintain a pristine appearance for a long time.

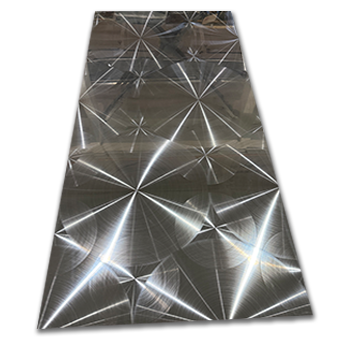

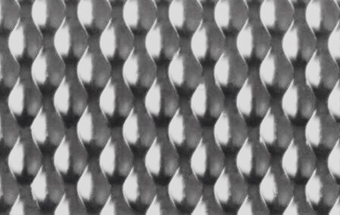

BWT’s Vibration finish stainless steel panels feature a variety of flat and 3D patterns. When used with a lighting system, they can transform your ceiling or walls into an art installation. The 3D patterns create beautiful light and shadow effects when illuminated.

Vibration stainless steel is made by polishing 316 stainless steel into mirror finish, and then forming it through a special physical treatment. Vibrating stainless steel has a smooth and flat surface, but can present 3D patterns.

BWT’s vibration finish stainless steel plates can be customized in various colors such as Black, Silver, Rose Gold, and Gold. Currently, BWT supports vibration finish stainless steel plates with a maximum width of 2m and a maximum length of 6m.

Vibration Stainless Steel Color Selection

Black Matt Finish Stainless Steel

Black Matt Finish Stainless Steel Charcoal Matt Finish Stainless Steel

Charcoal Matt Finish Stainless Steel Silver Matt Finish Stainless Steel

Silver Matt Finish Stainless Steel Champagne Gold Matt Finish Stainless Steel

Champagne Gold Matt Finish Stainless Steel Light Champagne Matt Finish Stainless Steel

Light Champagne Matt Finish Stainless Steel Copper Matt Finish Stainless Steel

Copper Matt Finish Stainless Steel Bronze Matt Finish Stainless Steel

Bronze Matt Finish Stainless Steel

Why Choose BWT

Our vibration stainless steel sheets are made from high-grade 304 and 316 stainless steel.These materials are strong and corrosion-resistant, making them suitable for use in crowded public places.

BWT has standardized production processes and strict production procedures.Each vibration stainless steel sheet undergoes precise measurements and visual checks to ensure flawless results.

BWT’s Vibration Finish stainless steel can offer flexible customization options such as thicknesses, dimensions, and surface treatments. Different shapes and bends can also be customized to meet the needs of the project.

BWT has a comprehensive service team covering stainless steel sheet design, production, installation, and after-sales service. Our service team can provide you with pre-sales consultation and rapid after-sales support.

Material Options

We offer vibration stainless steel sheets in two premium material grades: 304 and 316L.

304 stainless steel is more economical. 316L stainless steel offers superior corrosion resistance and weather resistance, making it recommended for environments with high humidity and salinity. It effectively resists corrosion, ensuring your project remains new for a long time. Furthermore, 316L stainless steel is stronger and has a longer lifespan, almost matching the lifespan of the building itself. Compared to 304 stainless steel, 316L stainless steel has lower maintenance and replacement costs, resulting in a higher cost-effectiveness over its entire lifecycle.

Vibration Techniques

We offer both machine grinding and manual grinding options to achieve a vibration finish. Machine grinding creates a uniform texture across large surfaces and is ideal for cost-effective mass production. Manual grinding offers greater flexibility for unique design variations, making each piece distinctive and highly customizable.

BWT’s vibration finish stainless steel is first polished to a mirror finish, then deeply ground to create patterns. The surface is smooth with no textured feel. Brushed stainless steel, on the other hand, undergoes a physical treatment on top of mirror finish stainless steel to create regular, tactile scratches. Compared to brushed stainless steel, vibration finish stainless steel is smoother and less prone to staining.

There are multiple ways you can use these sheets in your projects such as exterior and interior design elements. You can make your wall panels, kitchen and elevators more stylish by vibration using stainless steel sheets. If we talk about exteriors, you can use them in public restrooms. It can also be used in public places such as airports and hotels with high traffic, for ceilings, or for stainless steel column cladding.

Yes, vibration finish can cover fingerprints and scratches and that is why you can use it for high traffic areas and common places.

Vibration finish stainless steel requires a special anti-fingerprint treatment to effectively reduce fingerprints and scratches. Stains and fingerprints on the surface of vibration finish stainless steel can be cleaned with a simple wipe.

Yes, you can have customised vibration stainless steel sheets in size and thickness according to your needs. This can be done by cutting, bending and welding them.

These vibration stainless steel sheets require very low maintenance. You can easily clean them with soap or detergent as they are resistant to corrosion as well.

Vibration finish stainless steel treated with anti-fingerprint coating has a denser molecular structure on its surface, making it difficult for stains to penetrate. Stains can be easily removed by gently wiping with a mild detergent.

In the case of elevators, these sheets may provide a luxurious look and they will give them a modern style. They improve the aesthetics of the escalators.

Of course Yes, you can use these sheets in your interiors and also in your decorations. They will automatically give your living room a very good look.

These sheets are really durable and perform better if you compare their corrosion resistance properties. They don’t fade and work best if you are planning to use them for years.

The most popular industries are architectural, interior designs and in manufacturing of elevators. You may also find applications in the retail and hospitality industry, household appliances, the automotive and aerospace markets and many more.

Yes, we allow our customers to get designs and patterns of their choice. Just share your ideas and we will manage everything.

Yes, we offer samples of different types of sheets. You can select the best one according to your taste.

Other Finish Options

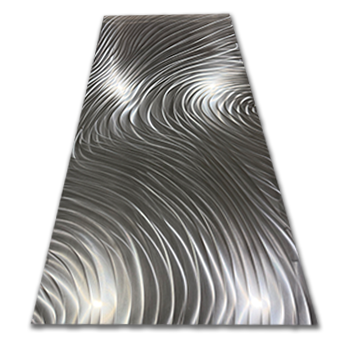

Water Ripple Stainless Steel Sheet

Water Ripple Stainless Steel Sheet Matt Finish Stainless Steel Sheet

Matt Finish Stainless Steel Sheet Multi Dimensional Stainless Steel Sheet

Multi Dimensional Stainless Steel Sheet Single Sided Stainless Steel Sheet

Single Sided Stainless Steel Sheet Double Sided Stainless Steel Sheet

Double Sided Stainless Steel Sheet