Best Mirror Stainless Steel Sheet Manufacturer

BWT is a mirror stainless steel sheet manufacturer in China. We can manufacture mirror stainless steel sheets in various colors and sizes, such as gold mirror stainless steel sheet, black mirror finish stainless steel sheet, blue mirror finish stainless steel sheet, and so on.

We use excellent surface treatment processes such as electrolytic coloring, vacuum titanium plating, welding, and grinding to produce mirror stainless steel sheets that are corrosion-resistant, scratch-resistant, and highly smooth.

Our mirror stainless steel sheets can be used in various scenarios, such as commercial building facades, interior decorative walls, furniture surfaces, etc.

Just tell us the size, quantity, and color you need, and we can customize the mirror stainless steel sheets to meet your needs. Contact us to get your quote now!

Different Mirror Stainless Steel Sheet BWT Can Make

Square 5mm thickness mirror stainless steel sheet for kitchen and decorative use, cutting service available, lead time 15-21 days.

0.3-3.0mm thickness mirror stainless steel sheet with bending, welding, punching, and cutting process, conforming to ISO and CE standards, customized length and width.

Gold colored mirror stainless steel sheet with bending, uncoiling, punching, welding, cutting, and other industries for ceiling decoration, customized color available, delivery time 8-14 days.

Flat 4×8 black mirror stainless steel sheet with bending, welding, and cutting process, CE and ISO9001 compliant, delivery within 7 days.

PVD colored mirror stainless steel sheet, thickness in 0.8-3.0mm, size available in 12m*2000mm, 1219*2438mm, 1219*3048mm, delivery time 15-21 days.

Mirror stainless steel sheet manufactured using the cold rolling process, available in lengths of 12000 mm and widths of 1000-2000 mm in 304 stainless steel for use in elevators, elevators and other scenarios.

ASTM compliant mirror stainless steel sheet, made of 316/304 stainless steel, thickness that can be selected from 0.3-3.0 mm, can be used for decorative architecture, using welding, uncoiling, punching, and other manufacturing processes.

Smooth surface, corrosion-resistant mirror stainless steel sheet. Made of 304/316 stainless steel, the thickness can be selected from 0.8-30mm, the length can be selected from 1-12m, the width can be selected from 500-2000mm, delivery time is 8-14 days.

Excellent Performance of BWT's Mirror Stainless Steel Sheet

BWT’s mirror stainless steel sheet is made from a high-quality stainless steel alloy that resists corrosion from UV rays, salt spray, rain, and other pollutants, making it suitable for use in outdoor environments.

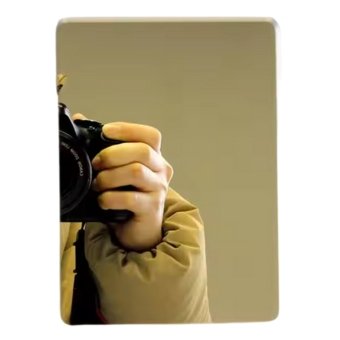

BWT’s mirror stainless steel sheet reflects light and the surrounding landscape, allowing the building to interact with the natural environment, giving people around it a fluid visual experience that enhances the building’s sense of modernity and technology.

BWT’s mirror stainless steel sheet is lighter than glass, reducing the building’s load-bearing requirements and making it easier to transport and install. In addition, its smooth surface is less prone to dust accumulation and can be wiped clean with a simple wipe, resulting in low maintenance costs.

BWT’s mirror stainless steel sheet can be used to extend the sense of space by utilizing its reflective qualities, which can reduce the sense of oppression in interior scenes where space is small. Reflected light enhances the lighting effect of the room, creating a brighter environment and increasing permeability.

BWT’s mirror stainless steel sheet remains stable in high-temperature environments such as kitchen stoves and meets the requirements of most building fire codes.

BWT’s mirror stainless steel sheet is scratch- and impact-resistant, making it suitable for use in high-traffic areas such as shopping mall walls and elevator interiors. It also maintains stable performance outdoors or in wet environments, eliminating the need for frequent replacement.

BWT’s mirror stainless steel sheet is easy to process and can be quickly shaped with laser cutting and bending techniques to suit individual design needs. Its lightweight material simplifies the construction process and speeds up installation.

Various Applications of BWT’s Mirror Stainless Steel Sheet

BWT’s mirror stainless steel sheet is widely used for curtain walling and roof cladding in commercial buildings and other public facilities. It can enhance a contemporary feel with reflective surfaces, while also giving a sense of flow to those around it.

BWT’s mirror stainless steel sheet is commonly used for backdrops or ceilings in hotels, shopping malls, and other venues. Reflected light can expand the sense of space. Mirrored partitions in offices or homes can separate spaces while keeping the room airy.

BWT’s mirror stainless steel sheet is commonly used for coffee tables, cabinets, screens, and other items. Its mirrored sheen enhances the modern look of furniture. In addition, it can be brushed to add texture to furniture.

BWT’s mirror stainless steel sheet is commonly used for elevator interiors and door covers. The light reflected by the mirror surface reduces the sense of enclosure. It can also enhance the durability of elevator compartments through the process of laminating cold-rolled steel sheets with stainless steel sheets.

BWT’s mirror stainless steel sheet is suitable for cooktops and hoods. The seamless design prevents grease residue and is easy to clean and maintain daily. It also meets food hygiene standards and can be used for kitchen countertops and utensil storage cabinets.

BWT’s mirror stainless steel sheet, with its mirrored reflective properties, can be used in landscape sculptures or exhibition installations to create a visual effect of light and shadow. Mirrored walls or ceilings can be used to extend the visual dimension in art galleries or technology exhibition halls.

Mirror-polished stainless steel sheets achieve an ultra-high reflectivity surface through advanced polishing techniques. This material is not only sturdy but also highly practical.

BWT’s production workshop uses very fine abrasives to polish the surface of stainless steel sheets, giving them a smooth surface and high reflectivity. This process results in stainless steel sheets with a more refined finish.

BWT’s mirror-polished stainless steel sheets can be customized in various colors, shapes, sizes, and thicknesses, with a maximum length of 10m, width of 2m, and thickness of 8mm. We can also bend the boards to create products or decorations of different shapes to meet your different project needs.

Mirror-polished stainless steel sheets are made of 304 and 316 stainless steel, are robust and durable with high corrosion resistance, suitable for various extreme environments, and come with a 25-year warranty.Regular surface maintenance and cleaning can be performed to prevent prolonged contact with water stains and extend the product’s lifespan.

In addition to mirror finishing of stainless steel, BWT can also perform surface treatments such as embossing, matte finish, and etching.Vacuum plating can also be performed according to color requirements.Meets the needs of projects in different scenarios

The Mirror Polished Stainless Steel Sheet boasts a high level of decorative realism, allowing for a wide variety of design combinations with different stainless steel surfaces. By utilizing the combination of mirror and matte finishes, BWT can even achieve a visually seamless splicing effect.

Depending on your needs, we can use different techniques to leave your logo or desired text on the mirror-polished stainless steel sheet.

(1)If the stainless steel surface is contaminated with fingerprints or dust, you can first gently wipe it with a clean, lint – free, and slightly damp cloth.

(2)If it cannot be wiped off, refer to the above situations and take corresponding cleaning measures.

(3)You can use a spray bottle to evenly spray the cleaning agent on a towel or the stainless steel surface, and then scrub it along the grain direction.

(4)After using the cleaning agent, rinse it with clean water to prevent the remaining cleaning agent from corroding the surface.

(5)Then wipe it dry with a dry towel or cloth until it shines.