One-Stop Laser Cut Stainless Steel Sheet Supplier

BTW is a Chinese laser cutting stainless steel sheet supplier with 10+ years of experience. We have produced over 12,500 pieces of laser-cut stainless steel sheet. Our laser cutting stainless steel sheets are widely used in building exterior decoration, hotel lobby ceilings, elevator doors, stairs, and other projects. Whether you want to use our laser-cut stainless steel sheet for high-end projects, furniture and appliances, or other projects, we will provide you with the best laser cutting stainless steel sheet solutions according to the needs of your project.

Our laser-cut stainless steel sheet is made of high-quality 304 or 316 stainless steel materials, and the quality is trustworthy. We can provide you with punching, laser cutting stainless steel sheet, engraving laser cut stainless steel sheet, hollowing laser cut stainless steel sheet, special-shaped laser cut stainless steel sheet, and other types of laser cut stainless steel sheet. Certainly, if your project requires other types of laser-cut stainless steel sheet, we can also support customization. You only need to tell us your design ideas or provide us with 3D drawings, and we can always provide you with one-stop laser-cut stainless steel sheet customization.

As China’s leading laser-cut stainless steel sheet factory, we have a 20,000㎡ production workshop, 100+ professional workers, and 20+ technical consultants to ensure that your laser-cut stainless steel sheet is delivered on time. It is worth mentioning that our laser-cut stainless steel sheet has been exported to 150+ countries around the world, and has provided suitable solutions for 1000+ projects in 30+ industries(such as elevators, billboards, ships, etc.). Contact us right now! Start your laser-cut stainless steel sheet customization journey!

Laser Cut Stainless Steel Sheet Customized This Week

You can find the type of laser-cut stainless steel sheet you need and get our best price by clicking each button below the product.

The tolerance does not exceed ±1%, the surface finish can reach 2B, cutting service is provided, and it has passed ISO9001 certification, cold rolling, and hot rolling. The color can be customized, the width is usually 1000-2000mm, the thickness is between 0.3-6mm, 3-16mm, and 18-100mm.

The thickness can be selected: 0.1 mm- 150 mm, the tolerance is strictly controlled within ±1%, widely used in the construction industry and the shipbuilding industry, reaching the ASTM standard, the width is between 600 mm- 2000 mm. Shipping, surface finish reaches BA grade.

The width can be selected from 1000mm to 2500mm, the length can be selected from 6 to 12m or customized according to your project requirements. We can provide bending, welding, uncoiling, punching, cutting, and other processing services, surface polishing.

Mainly used in food production equipment, chemical equipment, construction, aerospace, and other fields, with good corrosion resistance, high temperature resistance, and wear resistance. Length is 3-12m, width is 900-1500mm, and thickness can be customized.

Surface finish2B BA 2D 2BB No.3 No.4 are available, and have passed API, CE, RoSH, and other international certifications. They are widely used in the construction industry, with thicknesses ranging from 0.1-200mm and widths ranging from 10-2000mm.

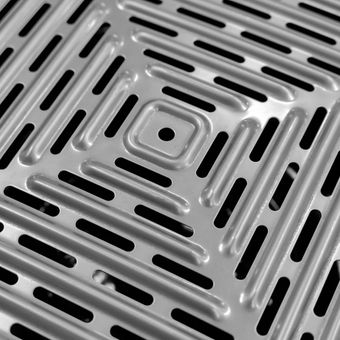

The tolerance is controlled within the range of ±5%, the width can be customized, and we provide welding, punching, cutting, bending, unwinding, and other processing services. We have passed the CE certification. Common patterns include round holes, square holes, oblong holes, and hexagonal holes.

Suitable for the construction industry, shipbuilding industry, petroleum, chemical industry, length can be selected 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc., thickness can be selected 0.3-3mm, width can be customized, the surface can be mirrored, embossed, etc.

Art theme, modern design style, can be used for interior decoration, and the size can be customized. All are made of high-quality 304 or 316 stainless steel, which can refract light well and bring a more high-end feeling to your project.

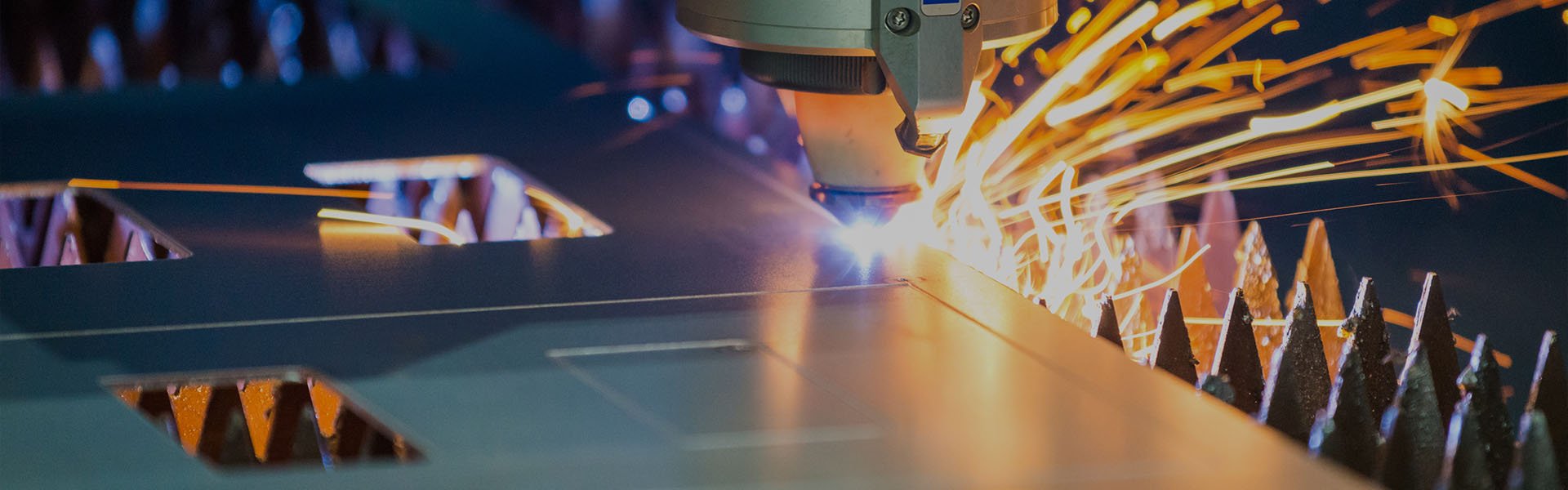

BWT’s Laser-Cut Stainless Steel Sheet process belongs to the field of cold precision laser cutting. It uses an extremely fine laser beam for cutting, resulting in a very clean kerf, allowing for the creation of complex and intricate patterns on stainless steel sheets. Furthermore, the heat generated during laser cutting is highly concentrated, minimizing the overall impact on the stainless steel sheet. Therefore, the sheet itself is less prone to deformation and discoloration after cutting, largely preserving the material’s original texture and strength.

BWT’s laser cutting applications are very extensive, not only for matte stainless steel, but also for various other stainless steel sheets with different surfaces, such as water ripple, mirror, multi-diemension, viberate, and more. When selecting sheet material, a solution should be developed based on the power of the laser system and the specific requirements of the project.

Some projects require the assembly of many delicate metal plates, so laser cutting technology is used. BWT’s laser cutting machines have precise CNC technology, which can accurately cut materials, effectively reducing material waste while ensuring the precision of the pattern. BWT metal always takes into account both the aesthetics and practicality of its products.

BWT’s sheets are made of 304/316 stainless steel, which has strong corrosion resistance, making it ideal for outdoor use. They also feature a special anti-fingerprint treatment, resulting in low cleaning costs.

Absolutely! Intricate shapes and patterns can be created on stainless steel sheets through chemical etching or laser cutting, with laser cutting being the preferred option. BWT’s laser cutting can produce incredibly fine patterns, such as custom tiger stripes, with a remarkably smooth surface.

BWT’s laser beam is highly concentrated, enabling extremely smooth and precise cuts. This is achieved through the meticulous operation of BWT employees and the perfect coordination between laser power, optical focusing accuracy, and the stainless steel sheet.

BWT’s laser cutting machines can cut sheets between 8mm and 3cm thick. Sheets thinner than 8mm may be damaged. Stainless steel sheets within this thickness range can be precisely cut without any damage or deformation.

Even after cutting, the sheet metal can still be used directly for bending, hyperboloiding, and other processing. Such sheet metal is very suitable for projects with high requirements for patterns and complex shapes. BWT metal has extensive experience in processing irregularly shaped parts and can undertake various complex projects.