Advantages of BWT’s Hairline Stainless Steel Sheet

Our hairline stainless steel sheet combines aesthetics, functionality, and practicality.

- Elegant Appearance

- Smooth to Touch

- Easy to Maintain

- Long-Lasting Performance

- Corrosion Resistance

- Versatile Applications

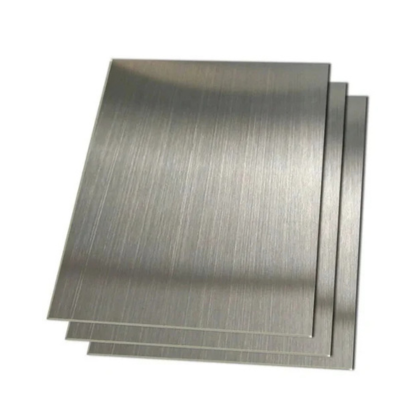

Reliable Hairline Stainless Steel Sheet Supplier

BWT has over 10 years of experience in providing hairline stainless steel sheets. Due to the smooth, low-reflective, and corrosion-resistant surface, our hairline stainless steel sheets are widely used in various industries. These hairline stainless steel sheets can be found in elevator doors and cabins, interior cladding, industrial equipment, furniture finishes, and hotel interiors.

We offer custom service for hairline stainless steel sheets. We provide three types of hairline finishes, including straight hairline, cross hairline, and diagonal hairline patterns. Other customization options include dimensions, strip widths, and materials such as 304 stainless steel and 316 stainless steel to meet the exact requirements of your projects.

Our hairline stainless steel sheets feature a stable surface treatment that ensures long-lasting performance without fading or rusting. The smooth surface resists dust accumulation and offers a comfortable tactile experience. Contact us today to get your hairline stainless steel sheets now!

Hairline Texture Types

Finely brushed, parallel lines that create a sleek and modern look.

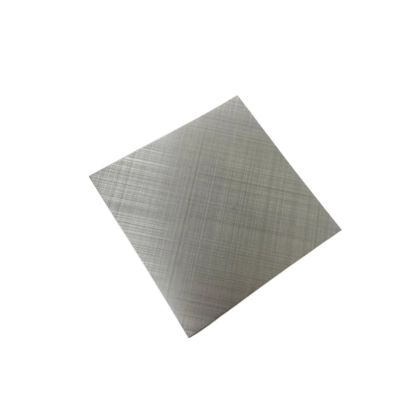

Distinctive grid-like pattern formed by intersecting brushed lines.

Brushed lines at an angle, providing a dynamic and stylish appearance.

Finely brushed surface with random grain patterns that minimize visible scratches and fingerprints.

Why Choose BWT for Hairline Stainless Steel

We use premium stainless steel sourced from reputable brands like TISCO, BAOSTEEL, and POSCO, ensuring excellent density and hardness.

We offer hairline stainless steel sheets in custom colors, thicknesses, and sizes to fit your project needs.

Each hairline stainless steel sheet goes through oil hairline processing, careful cleaning, and drying to ensure a smooth and consistent surface.

We pack the hairline stainless steel sheets with PVC film, waterproof paper, and wooden crates to keep them safe during shipping.

We carefully inspect each hairline stainless steel sheet to make sure it meets our standards, so you can get flawless products.

Material Selection

We mainly use two stainless steel grades for our hairline finish sheets: 304 and 316/316L. 304 is the most common choice due to its good corrosion resistance and versatility in many environments. For more demanding conditions, 316/316L offers superior corrosion resistance and better durability. Both grades are non-magnetic and provide excellent strength and long-lasting performance.

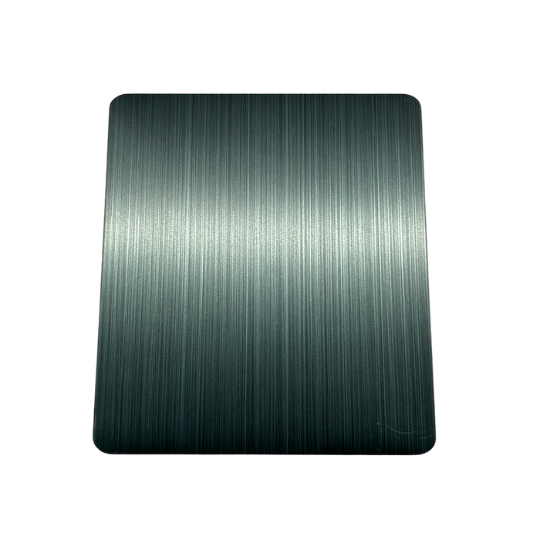

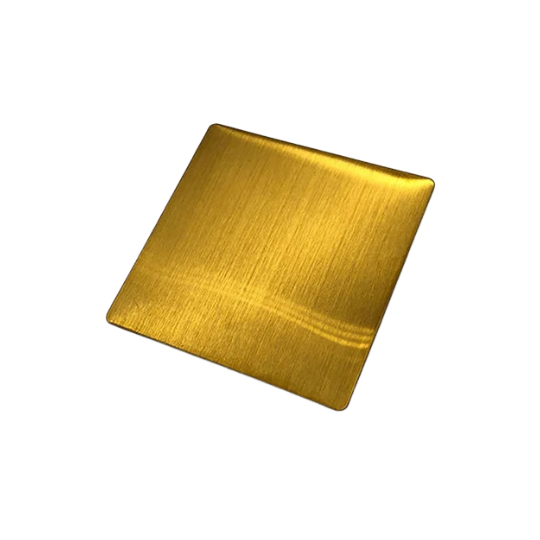

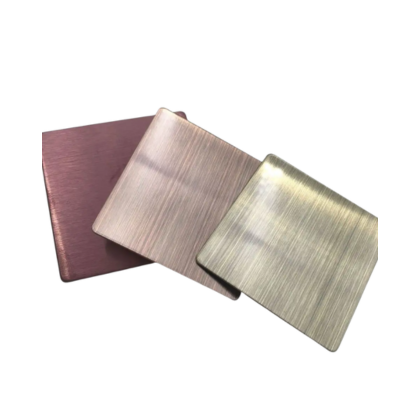

Color Options

Our hairline stainless steel sheets come in a range of refined colors, including champagne, copper, black, blue, silver, gold, and rose gold. These finishes enhance the appearance while preserving the material’s durability and corrosion resistance.

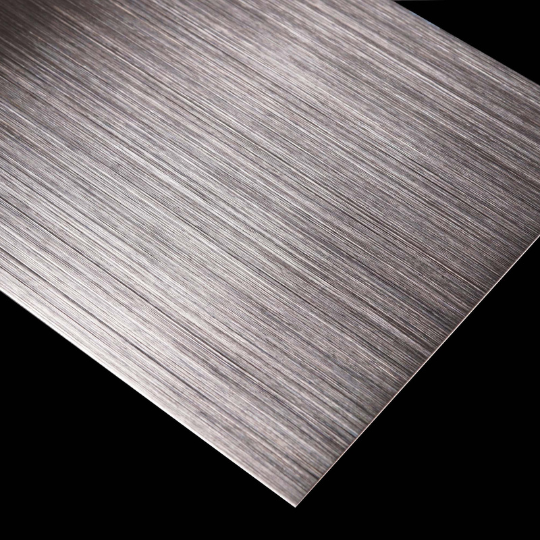

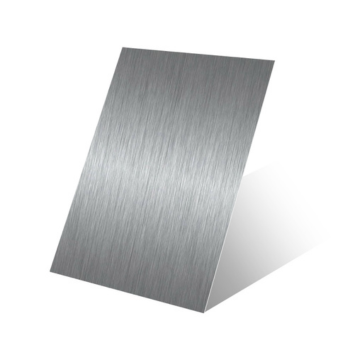

Check Our Latest Hairline Stainless Steel Sheets

Thickness: 0.3 mm – 3.0 mm

Color: Titanium Gold, Black, Rose Gold, Silver

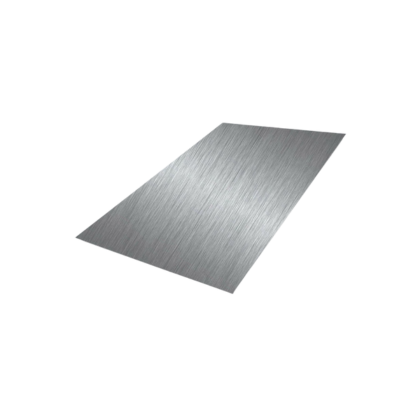

Thickness: 1.0 mm

Color: Natural Color

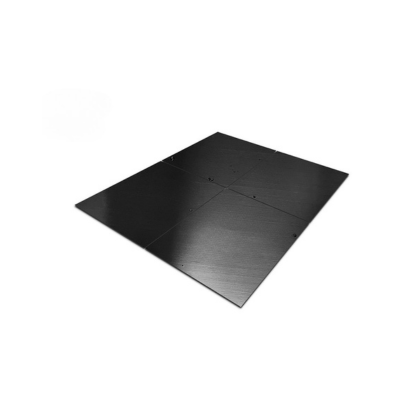

Thickness: 1.5mm, 2.0mm

Color: Black

Thickness: 0.8mm, 1.0mm, 1.5mm

Color: Black, Bronze, Gold

Thickness: 0.8mm, 1.0mm, 2.0mm

Color: Rose Gold

Thickness: 1.0mm, 2.0mm, 3.0mm

Color: Rose Gold

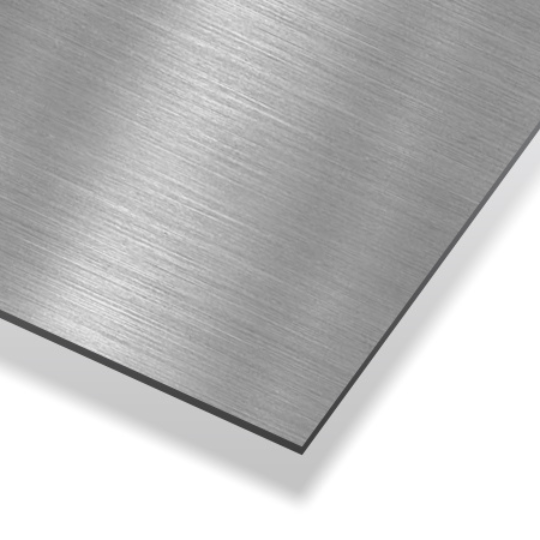

Thickness: 1.0mm, 2.0mm, 3.0mm

Color: Natural Color

Hairline stainless steel is widely used in architecture, interior design, elevator panels, kitchen appliances, escalators, and commercial spaces. It combines aesthetics with durability, making it ideal for both decorative and functional purposes.

Yes. Hairline finishes resist fingerprints and scratches better than mirror finishes. You can simply clean them with mild soap and water to keep the surface looking elegant.

Absolutely. We offer customization in material grades (304, 316), finish types (straight, cross, diagonal), dimensions, strip widths, and cut-to-length sizes.

Yes, especially when using corrosion-resistant grades like 316. Hairline finishes perform well outdoors due to their durability and ability to resist rust and fading under proper conditions.

Both finishes are low-reflective and have fine lines, but hairline finish stainless steel sheet has longer and more obvious lines, satin finish has shorter, softer lines, and looks more matte.

How to Make Hairline Stainless Steel Sheets

- Surface Preparation

Clean the stainless steel sheet to remove any dirt, oils, or contaminants that might affect the finish.

- Abrasive Polishing

Use abrasive belts or pads with medium grit (typically between 150 and 180 grit) to polish the surface of the stainless steel sheet.

- Surface Treatment

Apply a protective coating such as an anti-fingerprint layer or oil polish to enhance durability and maintain appearance over time.

- Final Cleaning and Inspection

Clean the finished surface carefully and inspect it under good lighting to ensure uniform texture and no defects.