We offer decorative stainless steel sheet fabrication services to meet clients’ diverse needs. Whether you are a contractor, architect, or building owner, BWT can provide one-stop fabrication services. Our fabrication services are tailored according to your requirements. We guarantee to turn your vision into life while maintaining cost-effectiveness and high-quality. With our years of expertise, BWT can provide endless fabrication services and solutions.

Fabrication Services We Provide

Different metal products need different ways to be made. At BWT, we use special techniques and standard methods to create the right shape for your custom applications. We use a variety of sheet metal fabrication methods to turn decorative stainless steel sheets into high-quality finished products.

This method is used to cut stainless steel sheets. It mainly involves shearing, sawing, and punching. Specialised metal cutting is also available such as water jet cutting and laser cutting for cutting thick stainless steel sheets.

This fabrication method is used for creating decorative stainless steel sheet into complex 3D shapes. It involves various processing such as bending, stamping, roll forming, curling, spinning, and stretching.

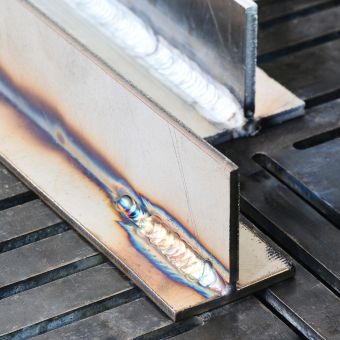

We offer sheet metal joining process for connecting two or more pieces of stainless steel sheets, creating an integrated structure. It involves mechanical joint, folding joint, adhesive joint, clinching joint, and more.

Decorative stainless steel sheets undergo various finishing process to create texture while improving appearance, functionality, corrosion resistance, and durability. It includes powder coating, etching, brushing, anodising, and more.

Advantages of Decorative Stainless Steel Sheet Fabrication Process

At BWT, we offer custom fabrication services to provide every client with design flexibility. Thus, providing you with endless options for your project design and feature.

Our metal fabrication processes allows each decorative stainless steel sheets to enhance strength, durability, weather resistance, and reliability.

We provide custom fabrication solutions to ensure that we meet your project requirements such as designs, space needs, and other factors, guaranteeing smooth installation process.

BWT fabrication process allows us to provide a wide range of finishes such as polished, powder-coated, and more. Thus, allowing your project to have improved aesthetic and appearance.

Quality Control on our Fabrication Process

- Thorough testing methods

- Following industry rules and standards

- Keeping track of materials and records

- Strict quality control steps

- Qualified expert and proper training

- Clear records and reports

- On-going process improvements

- Environmental commitments

Preparation Prior to Sheet Metal Fabrication

Proper preparation before stainless steel sheet fabrication is very important. Below are the preparation steps:

- Start with clear idea. Think about your desired thickness, size, shape, and how strong it needs to be for your project.

- Create a detailed design. After finalizing your idea, our engineers will make a drawing that show exactly what the product should look like.

- Workability analysis and review. The design is carefully checked to make sure it meets all the requirements.

- Sample Building. A prototype or a sample is made to test the design. This include cutting, assembly, shaping, and finishing.

- Testing the sample. Prototype is tested to help project owners see how it performs and give feedback before mass production.

- Full production. After the sample is tested and approved, full production begins.