Colored Stainless Steel Sheet Factory

- PVD color coating and electrolytic coloring

- Eco-friendly and no toxic chemicals

- Factory price, competitive price

Colored Stainless Steel Sheet Manufacturer

BWT is a professional manufacturer of colored stainless steel sheets and has cooperated with more than 10,000 customers for more than ten years. Our stainless steel sheets are painted with PVD color coating and electrolytic coloring. The color of stainless steel sheets is consistent, stable, and environmentally friendly. Thus, our colored stainless steel sheets have won a large number of customers’ positive feedback.

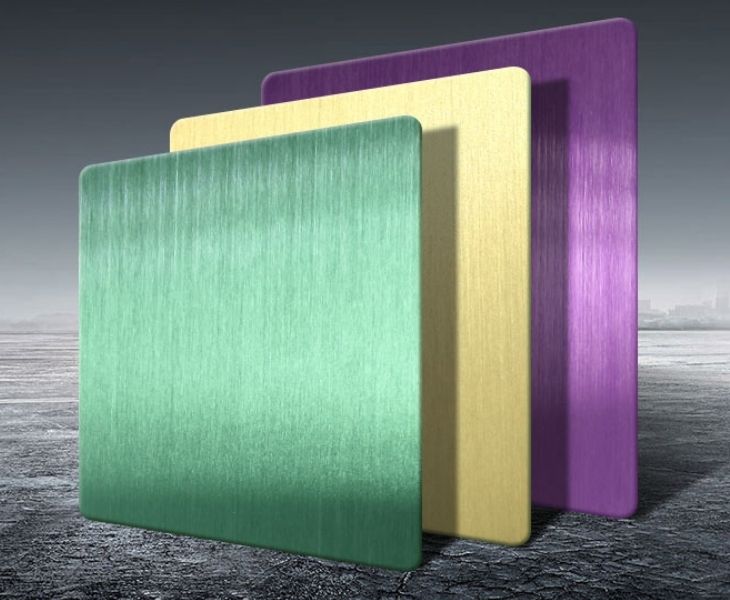

Our stainless steel sheets have a wide selection of colors to meet your project needs, such as black, gold, silver, brown, etc. We also provide you with a stainless steel color code chart to help you choose the right stainless steel plate color. In addition, we also support customized colors for your stainless steel sheets. Contact us to tell us your requirements, and start your business journey with colored stainless steel sheets.

BWT offers more than just the panels themselves; it provides a complete project service. BWT understands that every project has its unique creative element, therefore, BWT’s products incorporate “customization” throughout your building. We offer comprehensive support for your project.

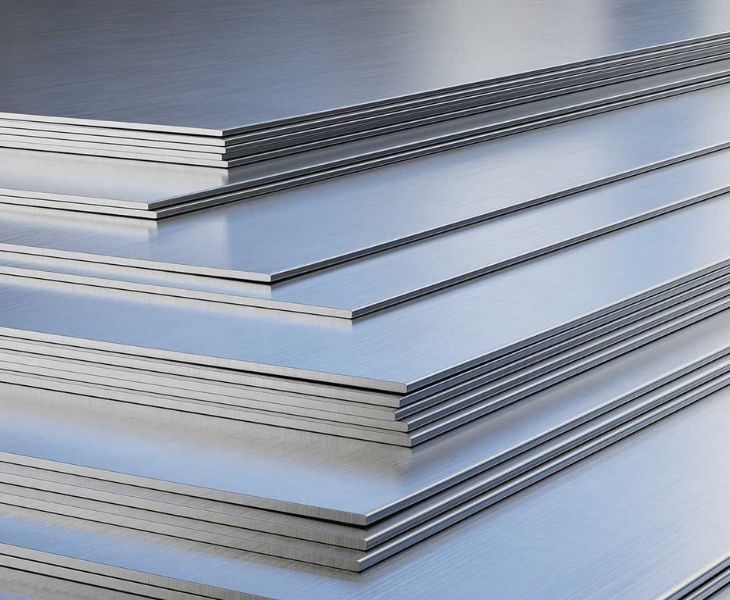

BWT owns a modern factory of over 20,000 square meters in China, ensuring that we have our own experience and understanding of our products and processes. Our complete set of production equipment and processes also ensures large-scale, standardized production when undertaking projects.

BWT’s services cover more than 200 countries and regions worldwide, accumulating global project experience across different climates, countries, and cultures. No matter where your project is located or how large it is, BWT can leverage its mature and efficient experience to serve you and provide a complete solution.

Different Types of Colored Stainless Steel Sheets We Made

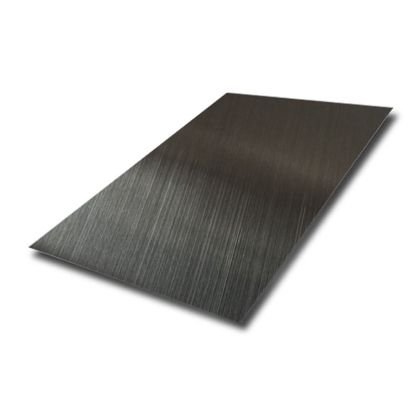

Mirror finish, full customization, 304 316 stainless steel, flat stainless steel plate

304/316 grade stainless steel, home decoration, standard seaworthy export packing

PVD color coating, with anti-fingerprint, flexible customization, and construction structure usage

304 stainless steel plate, full customization, decoration and construction application

304 316 grade steel, 8K surface finish, decorative sheet, professional design & after-sales team

304 316 stainless steel, industry, architecture, and decorative applications, with strict quality control

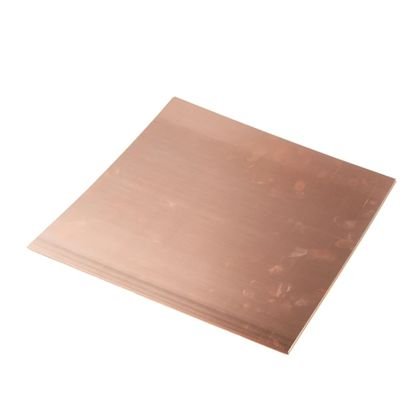

PVD coating with a bronze or gold finish, widely used for decoration, and with a customized thickness

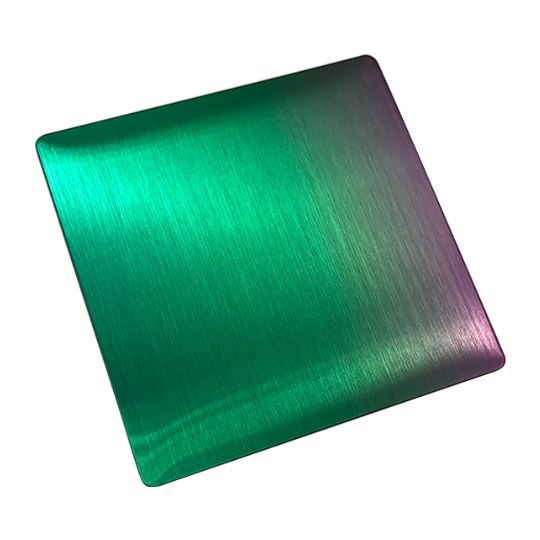

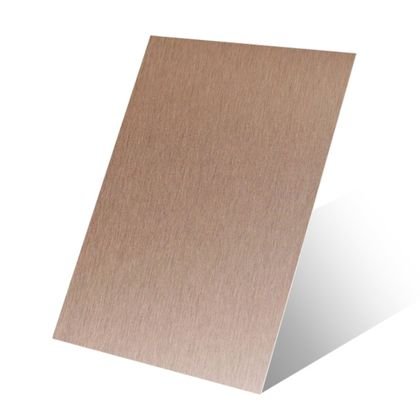

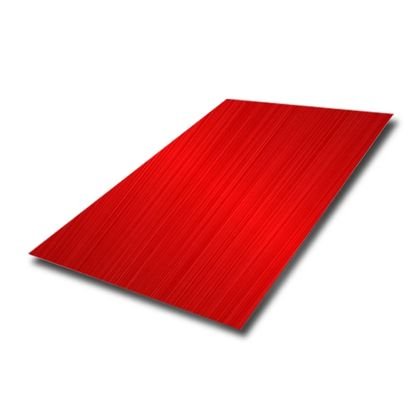

Brushed surface finish, 304/316 grade stainless steel, brown and red color, full customization

Different Colors of Colored Stainless Steel Sheet

Silver Stainless Steel Sheet

Silver Stainless Steel Sheet White Stainless Steel Sheet

White Stainless Steel Sheet Brown Stainless Steel Sheet

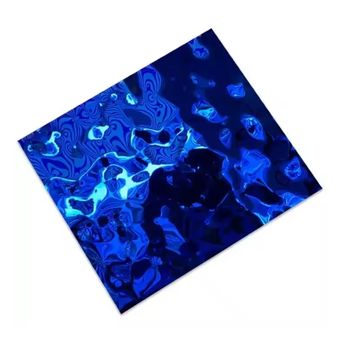

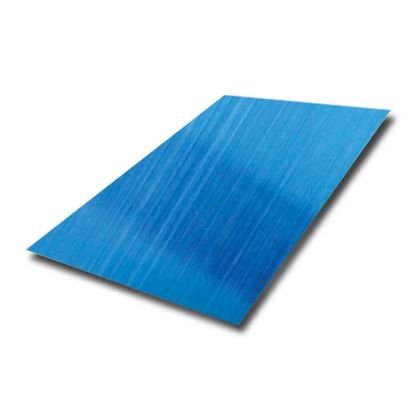

Brown Stainless Steel Sheet Blue Stainless Steel Sheet

Blue Stainless Steel Sheet Red Stainless Steel Sheet

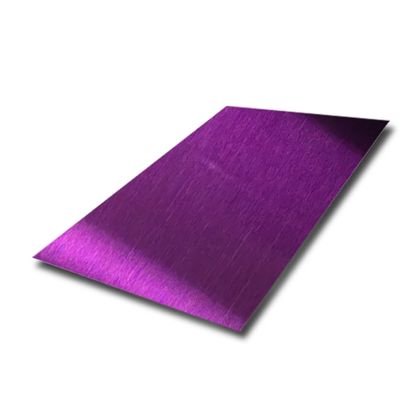

Red Stainless Steel Sheet Purple Stainless Steel Sheet

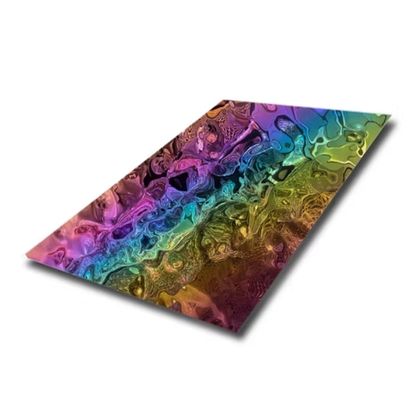

Purple Stainless Steel Sheet Rainbow color Stainless Steel Sheet

Rainbow color Stainless Steel Sheet

Colored Stainless Steel Sheet for Different Applications

Architectural Decoration

Architectural Decoration Ceilings

Ceilings Elevator Decoration

Elevator Decoration Advertising Signs

Advertising Signs Kitchen Cabinet

Kitchen Cabinet Partitions

Partitions Countertop

Countertop

Why 10000+ clients choose BWT?

PVD or electrolytic coloring technology ensures long-lasting, fade-resistant color that won’t peel or crack when bending.

Its excellent resistance to corrosion, UV rays, and daily wear makes it suitable for both interior and exterior architectural decoration applications.

Our colored stainless steel sheet sizes up to 1500×3500mm. We also provide custom thicknesses of less than 3 mm.

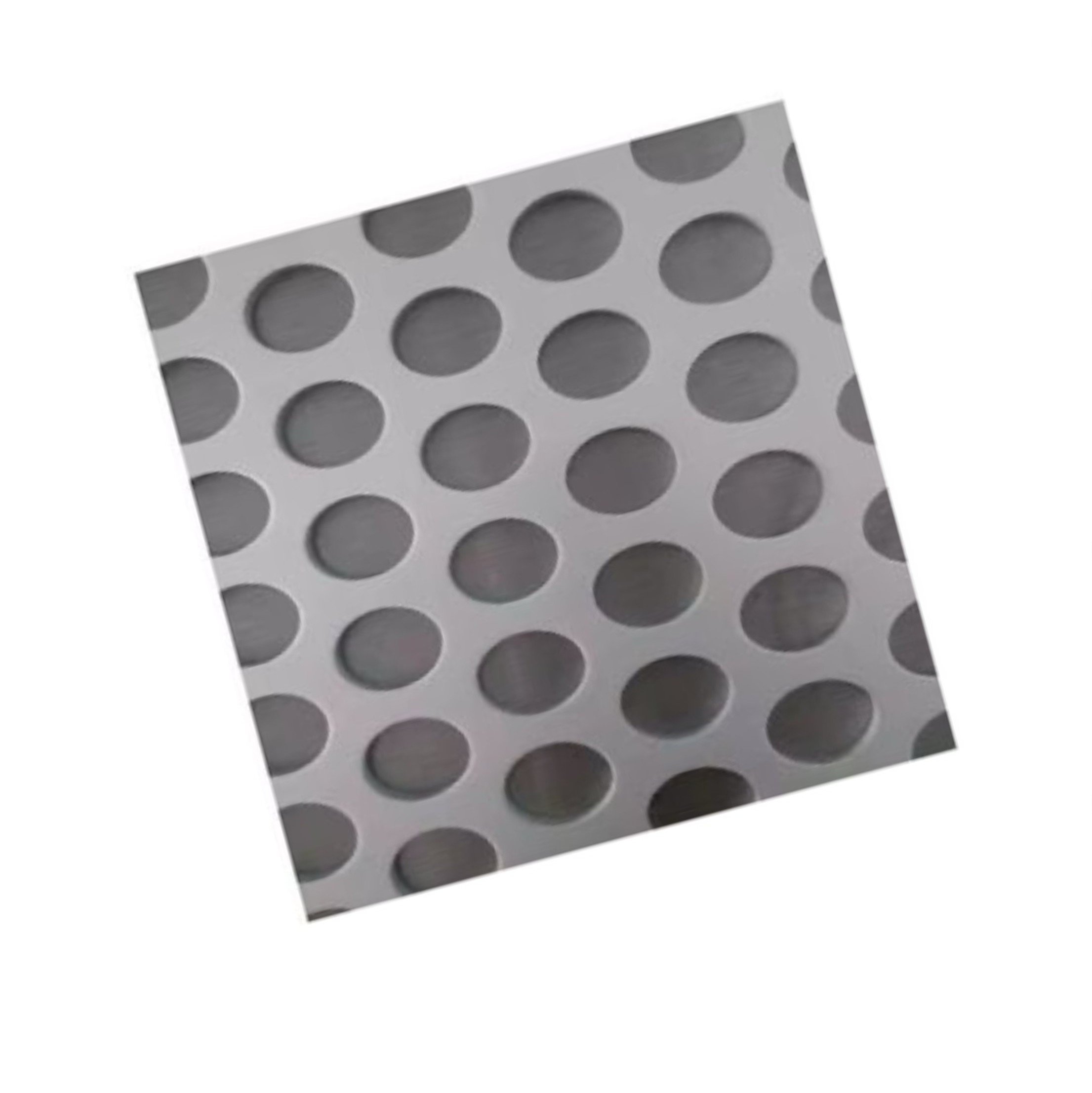

We support custom shapes, perforation, or cross-seam / I-seam designs for large surface installations.

Custom Length of Colored Stainless Steel Sheet

The standard lengths of our colored stainless steel sheets are 2440mm and 3050mm. Of course, we can also customize to your special requirements. But, due to the limitations of PVD and electrolytic coloring equipment, the length of colored stainless steel plates is limited. In addition, a length less than 3500mm can better ensure the uniform color of the stainless steel plate. In other words, if you choose colored stainless steel plates, we recommend that you control the length below 3500mm.

Different Surface Treatments of Colored Stainless Steel Sheets

Choosing suitable surface treatments for your colored stainless steels can make your project more eye-catching and impressive. From brushed, mirror finish, water ripple,sandblasting, to dull finish, BWT can provide you with high-quality and aesthetic colored stainless steel plates. In addition, our single-sided embossing series is also very fashionable as a decorative material. This series includes micro sandtex, new weave, linen, leather pattern, etc. No matter what surface treatment you need for colored stainless steel plates, BWT will satisfy you.

We provide 1219/1500/2000 mm standard widths for you to choose from, or a custom width less than 2000mm. If you have any problems with sizes, feel free to contact us.

No, our PVD and electrolytic coloring techniques can ensure the colors of the stainless steel sheet will never change or turn, even when they are exposed to UV rays.

We mainly use 304 and 316 grades. 316 is recommended for marine or outdoor high-corrosion environments.

Of course. We offer custom color matching, etching, embossing, perforation, and patterned finishes based on your design needs.

Yes. Brushed, matte, and PVD finishes offer excellent scratch resistance. We also offer anti-fingerprint coatings upon your request.

BWT’s colored stainless steel uses a PVD vacuum coating process. Through molecular fusion, the color penetrates into the interior of the sheet. This process enhances the durability of the sheet and the longevity of the color. Even if the surface is scratched, the sheet will not lose its original color. Furthermore, the molecular-level bonding ensures that the color will not fade even under prolonged exposure to natural sunlight.

BWT’s colored stainless steel sheets can have a lifespan similar to that of a building under normal conditions. With proper maintenance, their performance lasts even longer. In high-humidity, high-salt areas, it is recommended to clean the sheets regularly to remove surface salt water and water molecules, which will help the colored stainless steel sheets maintain their color and durability. Also, avoid sharp impacts; although the color and the sheet material are molecularly bonded, deep scratches will reveal the original color of the stainless steel.

Yes, BWT’s colored stainless steel sheets use 304/316 stainless steel as raw material. The material itself has strong corrosion resistance and durability, making it suitable for use as building facades in areas with extreme climates. Only simple daily maintenance is required.

Currently, commonly used colors for BWT colored stainless steel sheets include blue, rose gold, bronze, gold, and champagne gold. Custom colors are also available upon request.

Colored stainless steel sheets have a very high density, making them very easy to maintain and clean. For daily cleaning, simply remove surface water stains and dust. Gently wipe with a soft cleaning cloth. For stubborn stains, use a cleaning cloth and diluted detergent. Do not use strong cleaning agents, as these will corrode the surface of the colored stainless steel, affecting the molecular bonding and causing the color to fade.

BWT can customize colored stainless steel sheets in various sizes. Currently, we can customize PVD-coated stainless steel sheets with a maximum width of 2000mm and a maximum length of 9m. We can meet the specific needs of your projects, large and small.

Yes, the PVD coating forms a tight protective layer on the surface of the sheet. While it doesn’t completely prevent fingerprints, it does make the sheet easy to clean, effectively preventing stains from finger contact. It also makes cleaning stains easier and more effective than mirror-finish stainless steel. Stains can be easily wiped away with a cleaning cloth.

Yes, the process for BWT’s colored stainless steel sheets involves first cutting and polishing the raw materials, then applying PVD coating, followed by surface treatment with patterns, and finally welding. Welding can be performed on-site because BWT’s welds are made from the inside and will not damage the surface PVD coating. However, cutting may damage the coating or even scratch the surface of the sheet. We will perform all processing in the factory to ensure smooth on-site installation.

Common plating processes for colored stainless steel include PVD plating, traditional electroplating, and painting. BWT’s colored stainless steel sheets use PVD coating, a vacuum plating process that is more environmentally friendly and safer than traditional electroplating. It also provides longer-lasting and more wear-resistant colors than painting. Therefore, PVD vacuum plating is the optimal solution for coloring stainless steel.