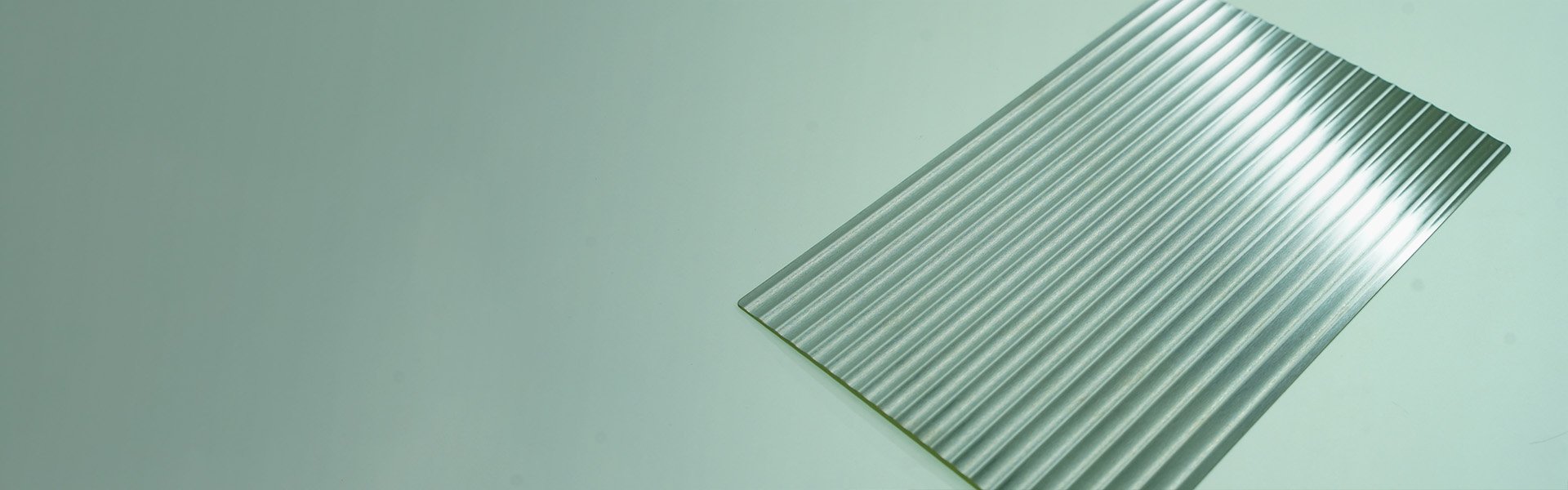

Corrugated Stainless Steel Sheet for Sale

Our corrugated stainless steel sheet has excellent fire, weather and corrosion resistance for your various application scenarios. Whether you need to use for marine industry, building fences, temporary building frames, or as noise barriers and decorative curtain walls, our corrugated stainless steel sheets can meet your needs in different industries for your projects.

The corrugated stainless steel sheet of BWT is made of high-quality 304 and 316 stainless steel.By cold rolled and molded, the unique corrugated structure gives it excellent resistance to wind pressure and deformation. Corrugated stainless steel sheets can not only satisfy the strength and load-bearing needs of your building enclosure, but also different corrugated shapes of the stainless steel sheets make your application scenarios with a modern aesthetic.

BWT has extensive experience in the processing of corrugated stainless steel sheets. For us, corrugated stainless steel sheets are more than just a building material, they are the perfect combination of structural strength and aesthetic design. Let us provide you with the best corrugated stainless steel sheets for your project. For more information, contact us now to start your corrugated stainless steel project journey and make your ideal design a reality.

Featured Corrugated Stainless Steel Sheet

For home art decoration,apartments and hospitals,wall stickers home decor,support customization for the size and color of corrugated stainless steel sheets.

High capacity,high separation efficiency,low pressure drop,large flexibility,suitable for all tower diameters,and strong resistance to corrosion of acid and alkali.

Suitable for hotel, villa, office, club, etc.The surface of the product is covered with pearl and cotton foam film,gold, can choose rose gold, black, customized color.

The process including bending, cutting, and decoiling, crafted from 304 or 316 stainless steel, can be easily customized in length, thickness, and width.

Exceptional durability and longevity,can customize the corrugated stainless steel plates to your specific needs,including welding, punching, cutting, bending.

Ensuring a long-lasting and corrosion-resistant finish,suitable for use in the home appliance industry,available in various thicknesses, widths, and lengths.

Length of 1400-1799 mm, 1800-2000mm, 2001-3600mm, 3601-3660mm, or customized,width of 665-1100mm,use standard seaworthy packing.

Width with options ranging from 600-1250mm, and thickness from 0.125-2mm, provide a range of processing services to meet your different requirements.

What are the characteristics of corrugated stainless steel sheets?

BWT’s corrugated stainless steel sheets are made of 316 stainless steel, characterized by high strength and toughness. This allows them to be used in extremely harsh environments, resulting in a long service life. Corrugated stainless steel sheets also possess excellent corrosion resistance, making them suitable for use in environments with high humidity, low temperatures, salinity, extreme cold, and chemical contamination. Low daily maintenance costs ensure your buildings maintain their lasting beauty.

The excellent durability of corrugated stainless steel sheets makes them particularly suitable for outdoor applications, and their lifespan is longer compared to other materials. Aesthetically, corrugated stainless steel sheets are suitable for roofing and wall cladding, and can even be used as sound insulation materials or artistic pieces.

Corrugated stainless steel sheets are not only durable, but their smooth surface treatment and robust raw materials also result in low maintenance costs, leading to a low total cost of ownership. Furthermore, only routine cleaning and maintenance are needed to ensure the long-term beauty of corrugated stainless steel sheets.

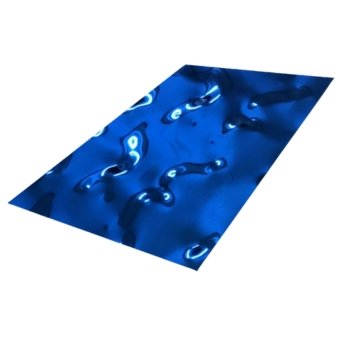

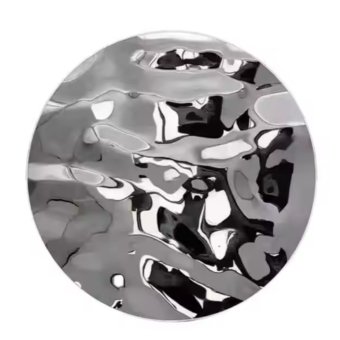

BWT’s corrugated stainless steel sheets undergo a special surface treatment that retains the inherent texture of the metal, giving the building a technologically advanced aesthetic. Different surface patterns and colors can also be customized to meet your diverse aesthetic needs.

Customized Corrugated Stainless Steel Sheet

BWT provides professional customized corrugated stainless steel sheet service, so that each corrugated stainless steel sheet can perfectly fit your project needs.Our corrugated stainless steel sheet is not only available in mill and mirror polished finishes, but also in a wide range of plating colors, such as gold, rose gold, black titanium, antique copper, etc.And you can choose unique corrugated shapes, including round curves, boxes, trapezoids, and wave patterns, are suitable for a wide range of scenarios such as architectural facade, industrial siding, piping systems, and so on. For different load-bearing requirements, we offer a wide range of thicknesses from 0.5mm to 3mm, and can add special features such as anti-corrosion coatings or noise insulation layers according to your specific needs. Whatever you have any needs for customization, just contact our team and we will provide you with the most suitable customization solutions, so that the corrugated stainless steel sheet can meet the functional needs of your project.

Our corrugated stainless steel plates are designed with standard installation slots and have special fixings, supporting screws, rivets and other installation methods, easy and efficient.

3-7 working days for regular corrugated stainless steel sheet, 7-15 working days may be needed for special customized sheets, you can contact us for expedited orders, we will arrange the production for you on priority basis.

We provide a standard sample book of our corrugated stainless steel sheets for free, if you need special customized samples, we will charge according to the customized details.

Yes. BWT corrugated stainless steel sheet roofing is a mature and systematic waterproofing solution. Its core lies in its professional longitudinal overlap and transverse interlocking design, combined with specialized sealing materials, forming multiple reliable barriers at the joints of the sheets. This system ensures that even in heavy rain, rainwater is kept out, effectively preventing it from seeping into the house.

Under normal conditions, the service life of these sheets easily exceeds 25 years. This is due to the inherent corrosion resistance and high strength of 316 stainless steel. If the environment is stable and basic routine maintenance is performed, the service life of the stainless steel sheets in a project can reach 25-40 years. Furthermore, the sheets themselves maintain stable color and are not easily deformed, exhibiting very strong stability throughout their entire lifespan compared to other materials.

Absolutely, and this is one of its core environmental advantages. BWT uses 304/316 stainless steel, a highly strong and recyclable material with a recycling rate exceeding 95%. This means that choosing our products not only gives buildings superior durability but also embodies the principles of a low-carbon and sustainable economy.

Absolutely. BWT corrugated stainless steel sheets have high inherent strength, and their corrugated structure provides excellent resistance to compression and bending. We will conduct rigorous structural calculations and designs based on the extreme weather data of the project site (such as wind pressure and hail), selecting suitable sheet materials and support installation schemes to ensure that the final project system can effectively withstand the impact of severe weather such as typhoons and hail.

BWT offers a rich and durable range of colors. We utilize advanced vacuum coating (PVD) technology, allowing color ions to penetrate deep into the sheet surface to form a dense coating. This results in extremely wear-resistant and corrosion-resistant sheets that maintain their new color and are resistant to fading. In addition to classic black, blue, rose gold, and bronze, custom colors of specific metallics are also available.

Yes, we can provide strong support. BWT has a global business network and installation experience with over a thousand customers. We can provide comprehensive services for your project, from design and drawing refinement to on-site technical guidance, and can coordinate professional construction teams to ensure that the products are installed correctly and efficiently, perfectly achieving the design effect.

The thickness of corrugated stainless steel sheets requires professional calculation, with the core objective being to find the optimal economic solution while ensuring safety. The selection is mainly based on dimensions, load (wind, snow), and sheet type. The larger the span and the heavier the load, the thicker the sheet material needs to be. For large-span projects, we can also recommend a composite solution of “corrugated sheet + honeycomb core” to enhance rigidity. Please provide your project parameters, and we will calculate and recommend the most suitable solution for you.

No, it’s not limited to standard corrugations. While BWT offers classic corrugated panels (such as high-wave, low-wave, and other types), we can also customize other different panels. We can create other three-dimensional textures (such as wood grain, stone grain, and geometric patterns) on stainless steel or corrugated panels through embossing, etching, and other processes, or combine them with mirror finishes, brushed finishes, and coloring, providing architects with more diverse creative means of expression.

Yes, and they are ideal for such highly corrosive environments. For general coastal areas, we recommend 316 grade stainless steel, which has stronger resistance to chloride ion corrosion. For heavily polluted industrial environments or extreme marine environments, we recommend using stainless steel surface treatment processes with superior corrosion resistance. Combined with professional system design, this ensures the long-term safety and aesthetics of the roof in harsh environments.

BWT has a mature packaging and transportation solution for its sheets to ensure safety. BWT sheets are securely bundled and packaged using custom-made wooden pallets, covered with protective film and foam padding to prevent scratches and deformation during long-distance transportation. Upon arrival, we recommend using specialized lifting equipment for vertical lifting; single-point or horizontal dragging is strictly prohibited, and a reasonable stacking area should be planned. BWT has a complete operating procedure to completely avoid damage caused by transportation and hoisting.

We provide in-depth technical support. Services include: system selection based on project drawings and specifications, and recommending appropriate materials; providing detailed load calculations and structural analysis to determine spacing, plate thickness, and material usage area; and customized solutions to ensure design feasibility for complex needs.

The core advantage of corrugated stainless steel sheets lies in their extremely low maintenance costs. Only routine safety checks and periodic cleaning of surface deposits (such as fallen leaves and dust) are needed. There is no need for regular repainting to match the sheet’s color. A professional inspection is required every few years, primarily checking the sealing of fasteners. These low-cost inspections can ensure the project operates smoothly for decades.