Why choose BWT’s matt finish stainless steel?

- 304 & 316 stainless steel

- High-quality and long-lasting

- Cut to size and shape

Matt Finish Stainless Steel Supplier

BWT is a Chinese matt stainless steel supplier with more than ten years of manufacturing experience, providing high-quality matt stainless steel materials. Whether you want to choose stainless steel materials for elevator decoration, building projects, modern furniture, or medical gadgets, our matte stainless steel is your most suitable choice.

BWT stainless steel uses a special matte surface treatment process. You can choose the matt finish that suits your project according to the application or decoration requirements. If you need, our team can also provide professional advice based on your application. Different surface treatments will bring different surprises to your project.

Our stainless steel offers a variety of color options for you. Whether you need black, charcoal, silver, gold, or other colors to decorate your project, we can provide a suitable color to give your building or appliance a stylish look.

Contact us now to order high-quality and beautiful stainless steel for your project.

Matt Finish Stainless Steel for Different Applications

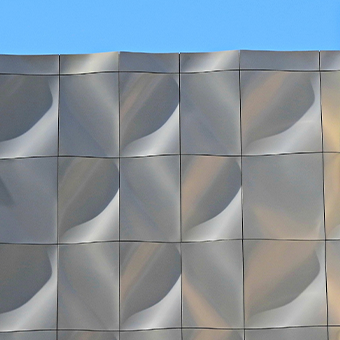

Outdoor cladding panels use the matt finish stainless steel to make the building eye-catching and impressive. And it can also improve the texture and weather resistance of the exterior wall.

Matt stainless steel is made of 304/316 stainless steel, which is waterproof, fireproof and corrosion-resistant, and is suitable for hospitals and commercial kitchens with high hygiene requirements.

Frosted stainless steel ceilings are commonly found in airports, museums and other places. The surface is anti-fingerprint treated, easy to clean, and enhances the sense of space in the building.

Brushed stainless steel is non-reflective, corrosion-resistant, can be treated with an anti-fingerprint finish, and is easy to clean, making it an ideal choice for elevator walls.

Matt stainless steel is widely used in residential and interior wall finishes. Its surface is beautiful, soft, and effectively prevents glare. The anti-fingerprint and scratch surface also makes it easy to maintain and clean in frequent use scenarios.

BWT Matt Finish Stainless Steel horizontal column cladding not only solves the problem of seams which are difficult to clean but also gives the matt stainless steel an overall minimalist and technological feel in the space.

BWT can be customized with seamless 12 meter stainless steel column cladding, up to 2 meters wide, and 0.8mm to 10mm thick. It is suitable for commercial spaces such as hotels and office buildings.

Frosted stainless steel uses 304/316 stainless steel, which has a stable structure and strong corrosion resistance. As a building decoration, it is durable and effectively enhances the beauty of the building itself.

Selection of Matte Finish Stainless Steel Colors

Black Matt Finish Stainless Steel

Black Matt Finish Stainless Steel Charcoal Matt Finish Stainless Steel

Charcoal Matt Finish Stainless Steel Silver Matt Finish Stainless Steel

Silver Matt Finish Stainless Steel Champagne Gold Matt Finish Stainless Steel

Champagne Gold Matt Finish Stainless Steel Light Champagne Matt Finish Stainless Steel

Light Champagne Matt Finish Stainless Steel Copper Matt Finish Stainless Steel

Copper Matt Finish Stainless Steel Bronze Matt Finish Stainless Steel

Bronze Matt Finish Stainless Steel

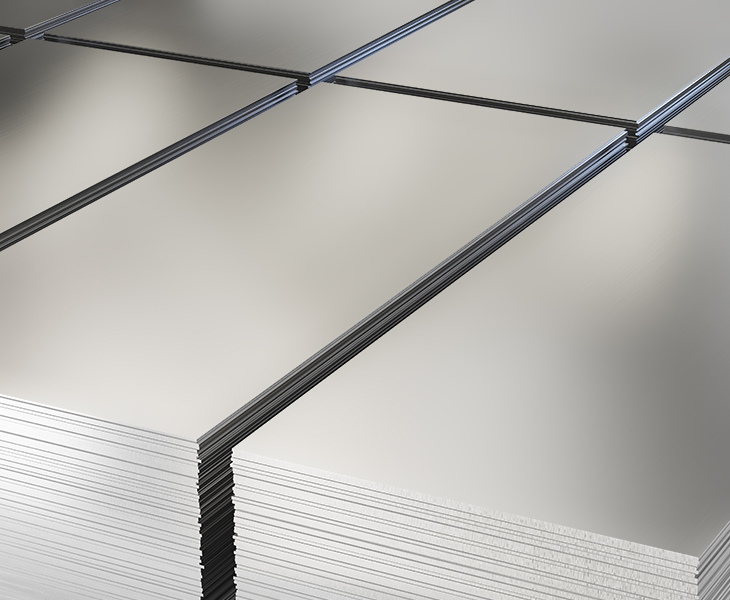

Matt Finish Stainless Steel’s Size Options

The thickness of matt stainless steel is determined according to different indoor and outdoor applications. For indoor decoration, the thickness of matt stainless steel is 0.8, 1.0, 1.5, and 2.0 mm. Outdoor curtain walls usually choose thicker matte stainless steel, which is 1.2, 1.5, 2.0, and 3.0 mm.

We can also cut matt stainless steel to different sizes for your project. We can meet your project’s needs with a width of less than 1450 mm and a length of less than 12 meters. Just tell us your needs or application requirements, and we can offer you the best matt stainless steel.

What's the difference between matt stainless steel and brushed stainless steel?

Both matt and brushed stainless steel achieve a matt finish.Matte stainless steel achieves this effect through a special surface treatment, resulting in a smooth feel. Brushed stainless steel achieves its matt finish by physically polishing the surface to create scratches, allowing you to feel the scratches.

Therefore, matt stainless steel is easier to clean than brushed stainless steel, and its smooth surface also gives it a softer texture.If you need to use it in a high-traffic public place, we recommend that you choose matt stainless steel that is easy to clean and has a touch of understated luxury.

Various applications of BWT matt stainless steel sheets

BWT’s matt stainless steel curtain walls and facades utilize 304/316L stainless steel as the base material, which is characterized by high strength, long lifespan, and corrosion resistance. Custom colors and bends can be provided to meet project requirements, giving your curtain wall a subtly luxurious metallic feel.

Using BWT’s matt stainless steel for ceilings diffuses indoor light, creating a soft, luxurious feel. Consider using it in high-end office buildings and shopping malls. Furthermore, the fingerprint-resistant matte stainless steel effectively reduces cleaning difficulty, requiring only simple daily maintenance to maintain its pristine appearance for a long time.

BWT matt stainless steel home decor panels undergo multiple polishing processes. First, the stainless steel substrate is mirror-polished, then a matt finish is applied, preserving its sturdiness and durability. Applying matt stainless steel to home decor can inject a luxurious and sophisticated element into your room, while its wear-resistant properties ensure the product remains as good as new over long-term use.

BWT’s matt stainless steel column wrapping can be customized in size. Currently, BWT has achieved a maximum length of 12 meters and a maximum arc length of 2 meters for seamless horizontal stainless steel column wrapping. The matt metallic texture not only extends the space but also gives the stainless steel column wrapping a low-key and simple decorative effect.

BWT's completed matt stainless steel project

Matt stainless steel sheets are used for cladding, roofing, and structural supports. You can also use them in modern luxury kitchen spaces and various interior design elements such as elevator panels and door frames.

Yes, surface treatments are important to get the required brightness of stainless steel sheets. They include wire drawing, sandblasting, titanium plating, etching, embossing and so on.

You can get customized Stainless steel sheets in terms of colour, shape, length, thickness and width. Customisation can make your project more beautiful. Just send us your requirements and we will handle everything.

Yes, you can definitely use these sheets in many medical equipments. Infact, these sheets are much more durable and look nice to eyes.

Of course, these sheets can give your furniture a totally new look. You can use them for making frames of chairs, tables and shelves.

Yes, you can use matt stainless steel for decorating the outer side of your real estate projects.

There is a big difference between brushed and sandblasted matt finishes. As you know from its name, we abrade the surface with a brush in brushed finishing. However, in sandblasted stainless steel finishing, abrasive particles are propelled at a high velocity to give it a pitted texture.

Care is really important and can increase the life of any project. You have to do regular cleaning with mild soap or detergent to preserve the matt finish and prevent corrosion. But you should avoid harsh chemicals and abrasive cleaners because they can become a source of scratching.

Yes, we can print your logo on these sheets. But it also depends on the type of stainless steel sheet. However, special surface primers and treatments are required for printing to prevent smudging. We use different techniques such as laser engraving and UV printing for printing logos.

Both are different if we compare their aesthetic look and functionally. Matt stainless steel is soft and modern while glossy steel is sleek and bright in appearance. You don’t need high maintenance for matt stainless steel like glossy steel. You can use matt finishes for high traffic areas while glossy finishes are used in luxury spaces mostly.

How to give stainless steel a matt finish?

We use several methods or techniques to create a matt finish on stainless steel, including mechanical and chemical methods. Sandblasting uses high pressure to spray the abrasive material onto the surface of stainless steel to create a grainy, matte finish.

Brushing uses abrasive belts to make fine lines on the surface of stainless steel to create a directional texture.

Grinding uses coarse abrasives to create a rough stainless steel surface.

Pickling uses chemical acids to remove the oxide layer, leaving the stainless steel with a dull surface.

Different types of stainless steel matt surfaces are suitable for different applications. Tell us about your application and we will recommend the most appropriate matte finish for you.