Top 2B Finish Stainless Steel Manufacturer In China

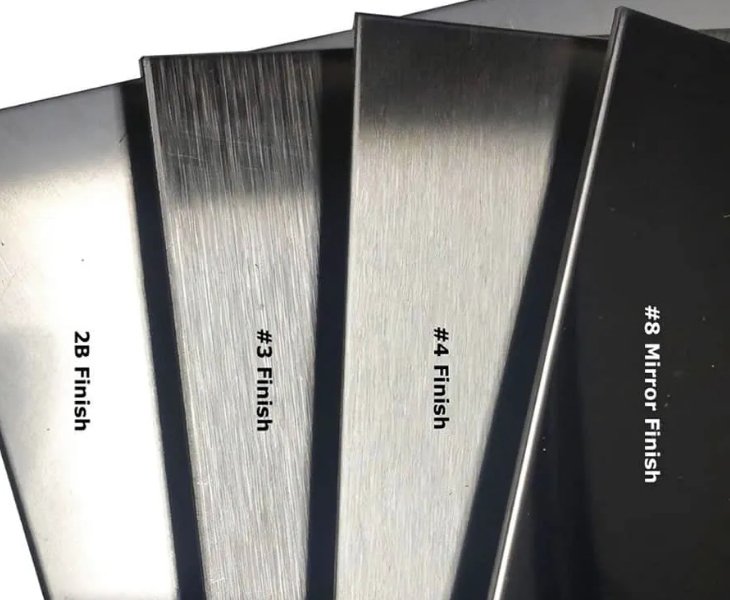

2B finish is the most common surface treatment process for stainless steel plates, which requires cold rolling, annealing, pickling, and slight flattening. vs other finishes, it is cheaper than No. 4 finish and has a wider range of applications; it is less rough and easier to clean than the 2D finish, and more uniform and smoother than the 1D finish.

BWT uses high-quality 304 and 316 stainless steel to make 2B finish stainless steel that meets different regional standards such as AISI, ASTM A480, JIS G4305, etc. Whether you are in the food processing industry, machinery manufacturing industry, construction industry, or other industries, the BWT high-quality 2B finish stainless steel will be perfectly applied to your projects.

BWT has 2 factories with a total area of more than 20,000 square meters. The site is equipped with imported multi-roll reversible cold rolling mills, continuous annealing furnaces, flattening mills, complete cleaning and drying systems, tension control systems, and surface detectors. Our operators are experienced and can accurately match the concentration of pickling liquid and skillfully control the temperature of the annealing furnace, ensuring that each 2B finish stainless steel has excellent performance and accurate size.

Contact BWT now to get the latest quotes. As one of the most professional OEM and ODM manufacturers in China, we offer you preferential wholesale prices and very low MOQ.

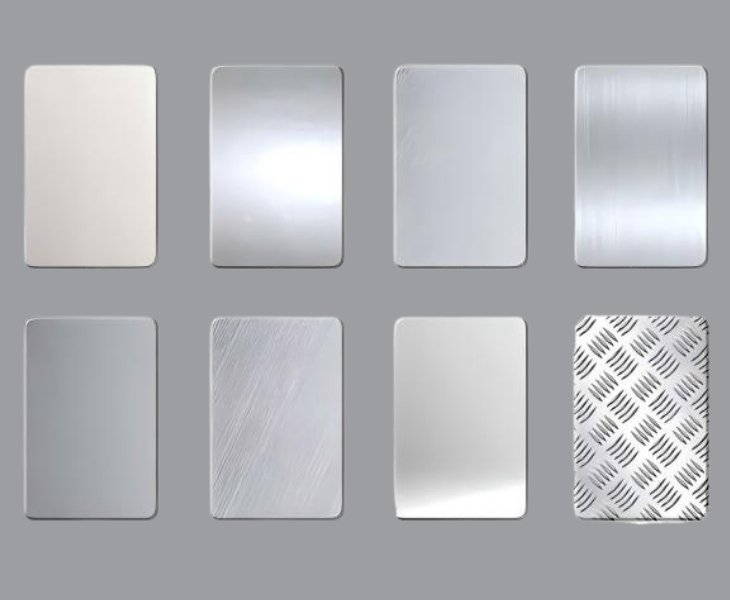

Various 2B Finish Stainless Steel We Make

Different Processes Of 2B Finish Stainless Steel

Stainless steel is rolled to the desired thickness through a cold rolling mill at room temperature. This step makes the surface of the material smoother and improves its strength.

The cold-rolled stainless steel is heated to a certain temperature and then slowly cooled to eliminate the internal stress generated during the cold rolling process. This process can also improve the ductility and toughness of the material.

The oxide layer and impurities on the surface of the material are removed using an acidic solution (such as nitric acid or hydrofluoric acid mixture). After pickling, the surface becomes smoother.

Finally, it is lightly calendared by a polishing roller to obtain a uniform semi-reflective surface. This step helps to further improve the surface finish.

Different Applications Of 2B Finish Stainless Steel

Building Decoration

Building DecorationElevator inner wall, escalator panel, ceiling, wall decoration, building curtain wall, door frame, and railing.

Advantages: smooth surface, easy to clean, resistant to atmospheric corrosion, suitable for high-visibility areas.

Food Processing And Catering Equipment

Food Processing And Catering EquipmentStorage tanks, production line conveyor belts, processing equipment, baking molds, tableware (knives and forks, plates), and commercial kitchen countertops.

Advantages: meet hygiene standards, resistant to acid and alkali detergents, and not easy to breed bacteria.

Medical And Pharmaceutical Equipment

Medical And Pharmaceutical EquipmentSurgical instrument trays, disinfection equipment shells, pharmaceutical reaction vessels, laboratory countertops, and fume hoods.

Advantages: strong corrosion resistance, easy sterilization, and meet clean environment requirements.

Household Appliances

Household AppliancesRefrigerator panels, dishwasher inner walls, stove shells, sinks, and shower room frames.

Advantages: both aesthetics and durability, anti-fingerprint, and daily wear and tear.

Industrial And Chemical Equipment

Industrial And Chemical EquipmentChemical storage tanks, pipes, valves, heat exchangers, and nuclear power plant cooling system components.

Advantages: high temperature resistance, chemical corrosion resistance, suitable for harsh industrial environments.

Machine Instruments

Machine InstrumentsIndustrial equipment control panels, gauge panels, and housings for high-precision measuring instruments.

Advantages: Suitable for humid or highly polluted environments, moderate reflectivity, and reduces visual fatigue during operation.

Superior Raw Materials

BWT’s 2B finish stainless steel uses 304 and 316 stainless steel, both of which are high-quality austenitic stainless steels, containing chromium, molybdenum, nickel, etc., which can give stainless steel more excellent properties. After strict pickling, return and other processes, a passivation film is formed to increase corrosion resistance and ductility, then the stainless steel can be used in various fields. The tensile strength of SUS304 stainless steel processed by BWT can reach 74,694 PSI, the yield strength can reach 70,343 PSI, and the elongation can reach 40%. Also, the SUS316 stainless steel we used contains 2-3% molybdenum, which has higher corrosion resistance than other stainless steels, allowing your project to work normally in extreme environments without reducing its service life.

Diversified Customization Options

BWT’s 2B finish stainless steel can be customized in terms of material, color, size, thickness, weight, etc. Our plate thickness ranges from 0.8mm to 10mm, and the side length of the cut stainless steel plate can be selected within the range of 12 meters. The colors include champagne gold, rose gold, bronze, black titanium, bronze, or customized colors. At the same time, BWT also provides logo customization and packaging customization services. We can print your logo or desired pattern where you want to highlight your brand positioning and expand the influence of your project. If you want decorative patterns such as swirl, water ripples, double-sided embossing, etc., we can also customize them for you.

304 and 316 stainless steel; they are the most suitable materials to make 2B finish stainless steel, and have diversified applications.

We have produced the ceiling of Miami Restaurant, Yancheng High-speed Railway C5 Block, Hangzhou E-sports Stadium, 15,000 square meters of architectural decoration in Doha, Qatar, etc. BWT has accumulated rich cooperation experience at home and abroad. We are a professional export manufacturer, and you can trust us completely.

We have PP bags, cartons, and wooden boxes, if you need special packages, we can customize them for you too.